Table of Contents

The annual dilemma of sourcing quality ethanol and the subsequent headache of dealing with its waste liquid. Not to mention the skyrocketing energy costs and environmental concerns that come with it. Sound familiar?

Well, worry no more. Ethanol dehydration doesn’t have to be a pain point anymore. With advanced technologies like PV Membrane, you can achieve efficient dehydration while saving on costs and reducing environmental impact.

So, buckle up! You’re about to embark on a journey that could very well revolutionize your procurement strategy and operational efficiency.

Why is Traditional Ethanol Dehydration So Problematic?

The methods of ethanol dehydration—distillation, azeotropic distillation, and adsorption. These methods have been the industry standard for years, but let’s face it, they’re far from perfect. First off, they’re energy hogs. The distillation process, for instance, requires a significant amount of heat energy to separate ethanol from water. This translates to high operational costs as you’re essentially burning money in the form of fuel or electricity.

But wait, there’s more. The energy consumption isn’t just a hit on your pocket; it’s a blow to the environment as well. The carbon footprint of these traditional methods is nothing to scoff at. We’re talking about substantial CO2 emissions that contribute to global warming.

And let’s not forget the waste. The distillation process produces a considerable amount of waste liquid that needs to be treated or disposed of, adding another layer of operational complexity and cost. This waste liquid often contains residual ethanol and other organic compounds, making it a hazardous material that poses environmental risks.

Moreover, the equipment used in traditional methods is often bulky, requiring a large footprint in your facility. This could be a logistical nightmare, especially if you’re operating in a space-constrained environment.

So, to sum it up, traditional ethanol dehydration methods are problematic because they are energy-intensive, environmentally unfriendly, produce significant waste, and require extensive infrastructure. It’s a quadruple whammy that no procurement officer or chemical engineer should have to deal with in this day and age.

What Makes PV Membrane the Game-Changer?

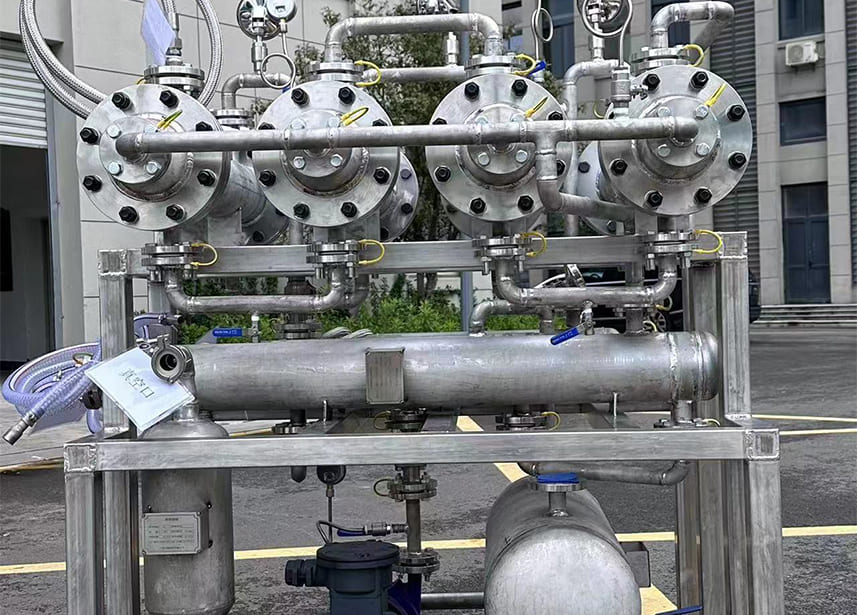

If traditional methods are the dinosaurs of ethanol dehydration, then Damo PV Membrane is the meteor that’s causing their extinction. Let’s dive into the nitty-gritty of why this technology is a game-changer. First and foremost, the operational parameters are a dream come true for any chemical engineer. With a maximum working temperature between 100-140℃ and a working pressure between 0.1-0.3 MPa, PV Membrane is engineered for peak performance.

But that’s just the tip of the iceberg. The pH range for the raw material is between 6.5 to 8.5, and the conductivity should be less than 5 μS/cm. What does this mean? It means that the membrane is incredibly resilient and long-lasting. You don’t have to worry about frequent replacements or maintenance, which is a massive win for procurement officers like myself.

Now, let’s talk about the technology’s core—its acid-resistant nanopore dehydration membrane. This membrane can endure a wide pH range of 3~8.5, making it versatile for various industrial applications. It’s not just about removing water; it’s about doing it efficiently and effectively through surface-adsorption and molecular-sieving mechanization.

And did I mention the energy savings? Oh, you’ll love this part. The operational energy consumption is so low that it can save over 80% of steam energy compared to traditional distillation systems. Imagine the cost savings and the reduced carbon footprint!

So, in a nutshell, PV Membrane is the game-changer because it’s efficient, durable, versatile, and environmentally friendly. It’s the kind of innovation that makes you wonder, “Why didn’t we switch to this sooner?”

How Does PV Membrane Work?

Alright, let’s get down to brass tacks and talk about the magic behind PV Membrane. At its core, this technology employs an acid-resistant nanopore dehydration membrane. This isn’t just any membrane; it’s designed to withstand a pH range of 3~8.5. That’s right, this bad boy is tough and versatile, making it ideal for a wide array of industrial applications.

Now, let’s talk hydrothermal stability. In layman’s terms, this membrane can take the heat and keep on ticking. It’s designed to operate efficiently within a temperature range of 100-140℃. This high thermal stability ensures that the membrane doesn’t degrade over time, providing you with a long-lasting and reliable solution.

But what really sets PV Membrane apart is its high separation performance. The membrane employs surface-adsorption and molecular-sieving mechanization to effectively remove water from organic solutions. This is where the science gets sexy. The pore size of the permeation membrane is 0.4 nm, strategically sized between the molecular size of water and organic solvents. This allows for precise and efficient separation, ensuring low organic content in the permeate.

And let’s not forget about energy efficiency. Traditional methods, eat your heart out! PV Membrane’s operational energy consumption is so low that it saves over 80% of steam energy compared to traditional distillation systems. And the cherry on top? Zero wastewater or waste-gas generated. That’s right, it’s as green as it gets.

So, to sum it up, PV Membrane works by utilizing a robust and efficient membrane technology that offers high separation performance, energy efficiency, and environmental friendliness. It’s the full package, folks!

What About Waste Liquid Management?

Waste liquid management—the Achilles’ heel of traditional ethanol dehydration methods. But with PV Membrane, it’s a whole new ball game. One of the standout features of this technology is its ingenious waste liquid management system. Let’s break it down.

The tail end of the vacuum unit is equipped with a condensation recovery system. This isn’t just a fancy term; it’s a game-changing feature. What it does is simple yet brilliant: it recovers and condenses the waste liquid, effectively eliminating the need for additional disposal methods.

Now, why is this a big deal? Well, for starters, it saves you a ton of money. Waste liquid disposal is not just a logistical challenge; it’s also a financial burden. Traditional methods often require you to treat the waste liquid to remove hazardous materials, and sometimes you even have to pay to dispose of it safely. With PV Membrane’s condensation recovery system, those costs are slashed dramatically.

But the benefits don’t stop at cost savings. This feature also has a significant environmental impact. By recovering and reusing the waste liquid, you’re reducing your carbon footprint and contributing to a more sustainable operation. It’s a win-win situation for both your bottom line and Mother Earth.

And let’s not forget compliance. Environmental regulations are getting stricter by the day, and failure to manage waste liquid properly can result in hefty fines and legal troubles. The condensation recovery system ensures that you’re always on the right side of the law.

So, in a nutshell, PV Membrane’s waste liquid management system is a triple threat—cost-effective, environmentally friendly, and compliant. It’s the kind of innovation that makes you wonder why you ever put up with traditional methods in the first place.

Is PV Membrane Environmentally Friendly?

The million-dollar question in today’s eco-conscious world. Is PV Membrane environmentally friendly? The short answer is a resounding “Yes!” But let’s not stop at one-word answers; let’s delve into the details.

First off, let’s talk about wastewater. Traditional methods often produce a significant amount of wastewater that needs to be treated, which is both costly and harmful to the environment. PV Membrane, on the other hand, generates zero wastewater. That’s right, not a drop!

And what about waste-gas? Another zero! No harmful emissions are released into the atmosphere during the dehydration process. This is a massive step forward in reducing the industry’s carbon footprint and aligns perfectly with global initiatives to combat climate change.

But the environmental benefits don’t end there. The technology’s low operational energy consumption means you’re using less fuel or electricity, further reducing your environmental impact. Imagine cutting your energy consumption by over 80% compared to traditional methods. That’s not just cost-saving; it’s planet-saving!

Moreover, the condensation recovery system we discussed earlier also plays a role in making PV Membrane a green technology. By eliminating the need for additional waste liquid disposal, you’re reducing the amount of waste that ends up in landfills or water bodies.

So, to wrap it up, PV Membrane is the epitome of green technology. It produces zero wastewater, zero waste-gas, consumes less energy, and even manages waste liquid efficiently. It’s not just a step but a giant leap towards a more sustainable and environmentally responsible industry.

How Do I Monitor the Dehydration Process?

The million-dollar question in today’s eco-conscious world. Is PV Membrane environmentally friendly? The short answer is a resounding “Yes!” But let’s not stop at one-word answers; let’s delve into the details.

First off, let’s talk about wastewater. Traditional methods often produce a significant amount of wastewater that needs to be treated, which is both costly and harmful to the environment. PV Membrane, on the other hand, generates zero wastewater. That’s right, not a drop!

And what about waste-gas? Another zero! No harmful emissions are released into the atmosphere during the dehydration process. This is a massive step forward in reducing the industry’s carbon footprint and aligns perfectly with global initiatives to combat climate change.

But the environmental benefits don’t end there. The technology’s low operational energy consumption means you’re using less fuel or electricity, further reducing your environmental impact. Imagine cutting your energy consumption by over 80% compared to traditional methods. That’s not just cost-saving; it’s planet-saving!

Moreover, the condensation recovery system we discussed earlier also plays a role in making PV Membrane a green technology. By eliminating the need for additional waste liquid disposal, you’re reducing the amount of waste that ends up in landfills or water bodies.

So, to wrap it up, PV Membrane is the epitome of green technology. It produces zero wastewater, zero waste-gas, consumes less energy, and even manages waste liquid efficiently. It’s not just a step but a giant leap towards a more sustainable and environmentally responsible industry.

Conclusion

So there you have it. PV Membrane not only solves the problem of ethanol dehydration but does so in an efficient, cost-effective, and environmentally friendly manner. It’s time to make the switch and say goodbye to those annual headaches.

That’s it, folks! For more information on our PV Membrane technology, feel free to visit here.