Advanced pervaporation systems, membranes, and modules for efficient separation processes

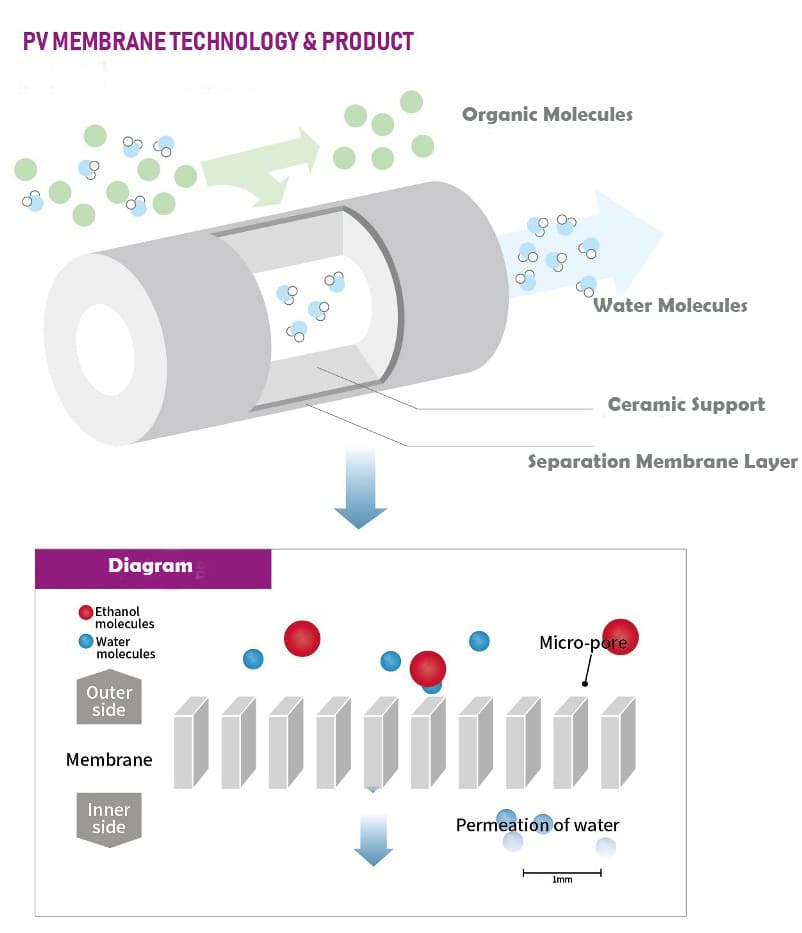

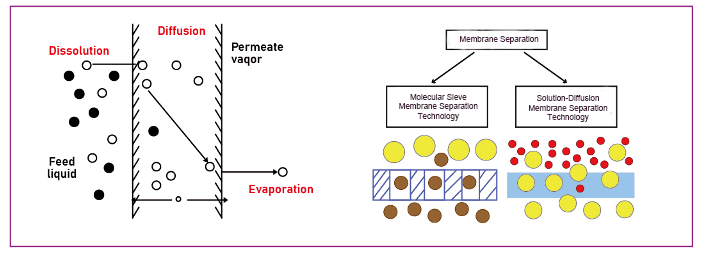

The main idea behind pervaporation membrane separation technology is to use the differences in how quickly each component in a liquid mixture dissolves and spreads within the membrane. The pressure differences created across the membrane allow for the separation of the components in the liquid mixture.

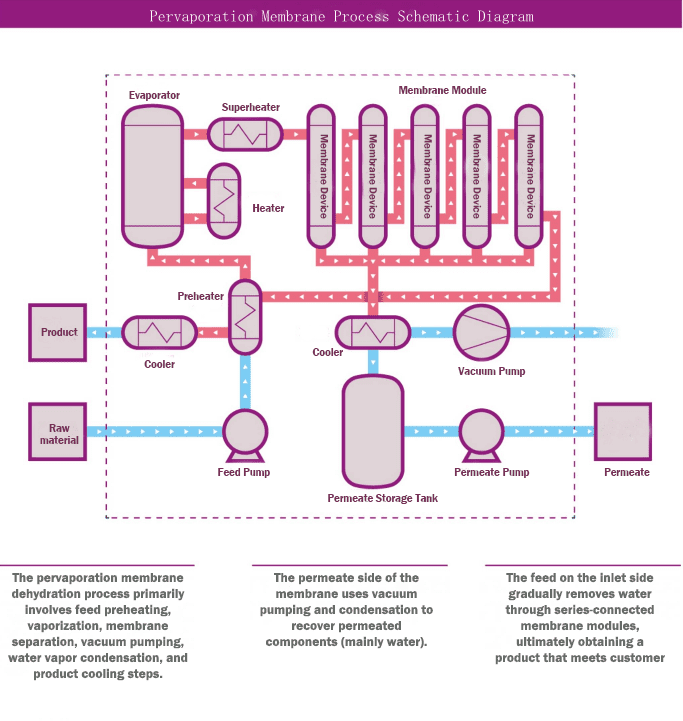

For example, when dehydrating organic solvents, the water-containing solvent is preheated and vaporized before entering the membrane module. A vacuum is maintained on the other side of the membrane to create a low-pressure environment. Water molecules pass through the membrane more easily, driven by the pressure difference, which removes water from the solvent. This results in a dehydrated organic solvent product at the outlet, while the components on the other side of the membrane are condensed and sent to wastewater treatment.

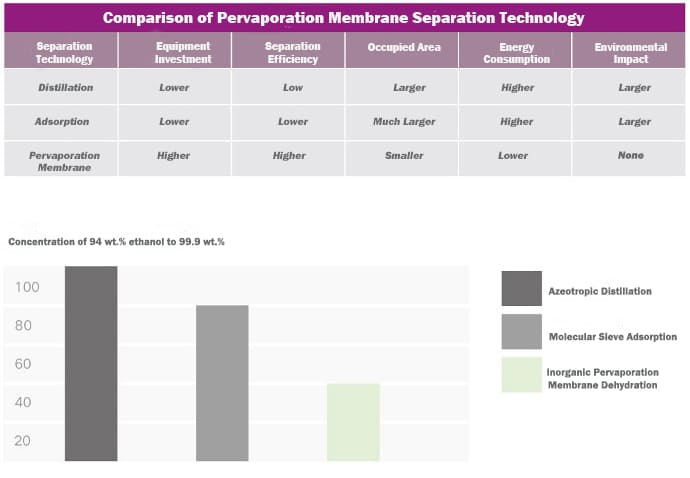

Pervaporation membrane separation technology is a highly efficient separation method that utilizes the different rates at which components dissolve and spread within the membrane to separate mixtures. Unlike traditional separation methods, this technology is not affected by whether the mixture is prone to boiling, making it an ideal solution for heat-sensitive systems and substances with constant boiling points.

Additionally, the technology is highly effective for dehydrating organic solvents that are close to boiling. This is achieved through the use of specialized membranes that allow the solvent to selectively pass through, leaving behind the water or other components that need to be removed.

One of the biggest advantages of pervaporation membrane separation technology is that it does not produce secondary pollution. The process operates at lower temperatures, making it more energy-efficient and environmentally friendly than other methods.

Furthermore, pervaporation membrane separation technology is easy to scale up and integrate with other processes, making it an attractive option for many industries. Overall, this technology offers a range of benefits that make it a valuable tool for separation and purification in the chemical industry.

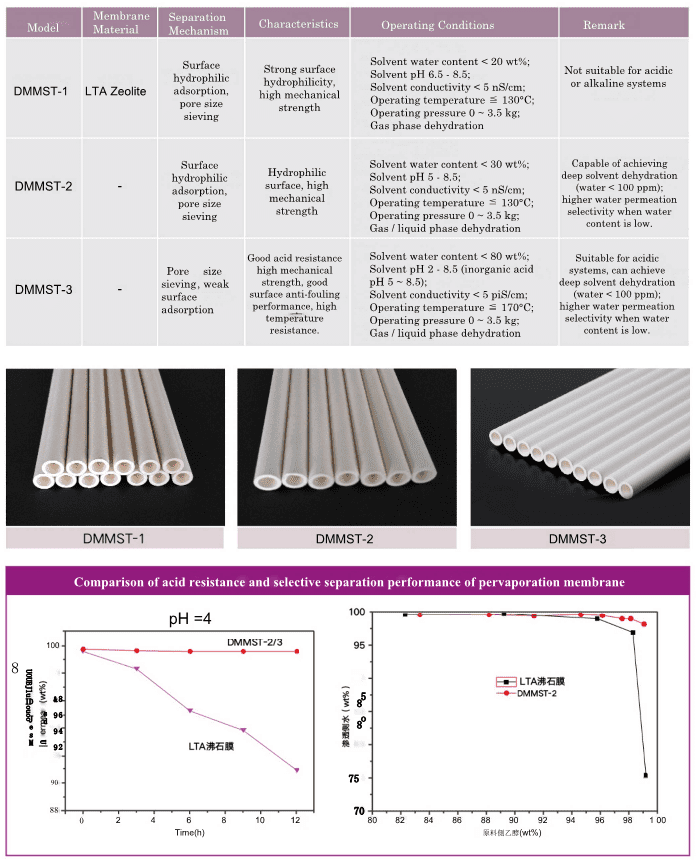

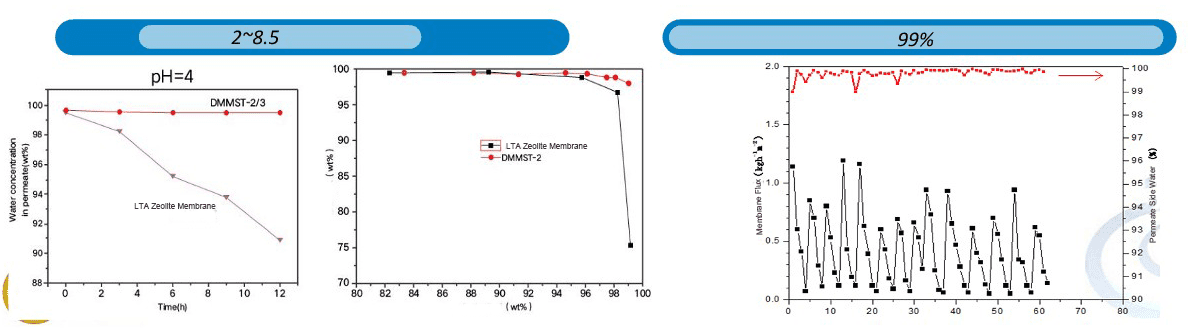

Damo’s Pervaporation Dehydration Membrane (DMMST-2/3) boasts high separation efficiency, with a product yield of over 99%, and low product concentration in the permeate, which is less than 1%.

The acid-resistant Damo membrane product (DMMST-3) is designed to withstand pH levels of 2-8.5, making feed pretreatment easier. It can effectively dehydrate organic solvents, even when the solvent undergoes chemical changes after heating, without compromising membrane performance.

This acid-resistant pervaporation membrane exhibits high hydrothermal stability, and can achieve organic solvent dehydration under liquid phase conditions, at mild operating conditions that are generally below the solvent boiling point. The process is simple, with no phase change, and Damo possesses fully independent intellectual property rights.

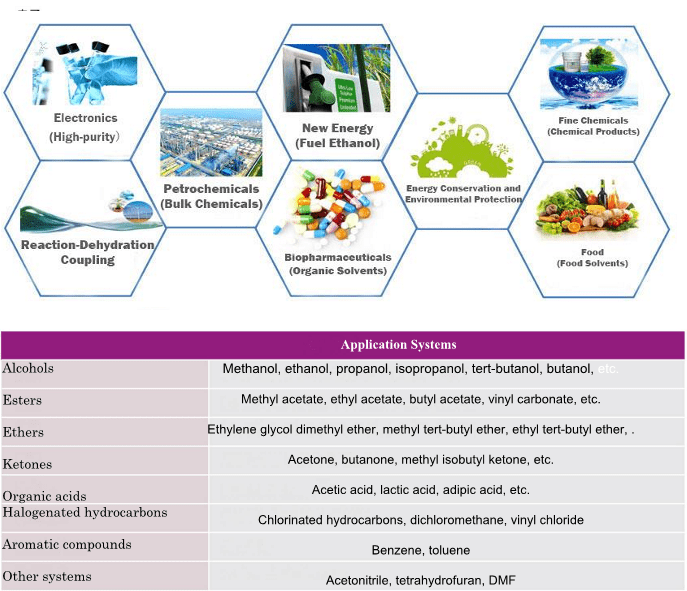

New energy, petrochemicals, coal chemicals, biopharmaceuticals, fine

chemicals, electronics, food, environmental protection, and other

industries

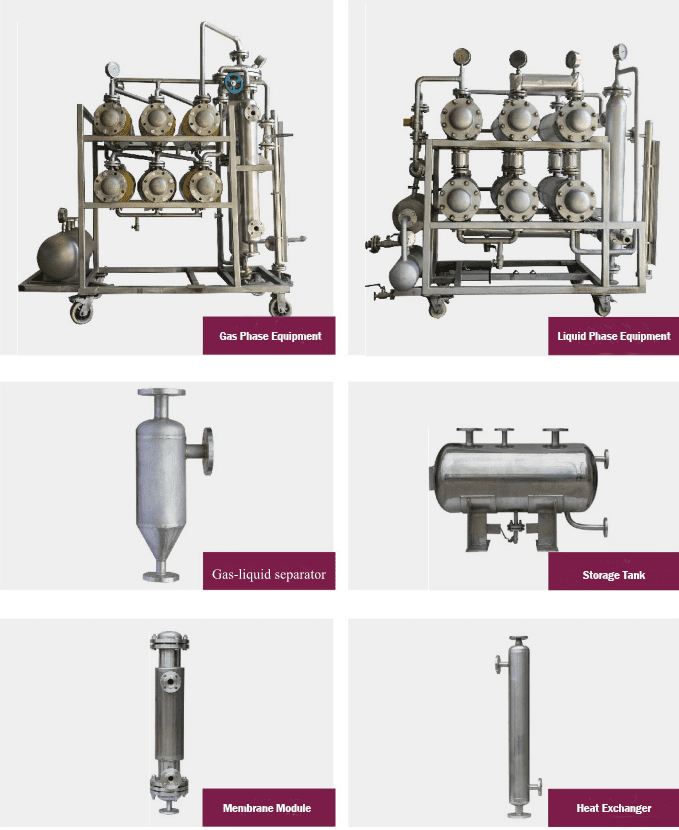

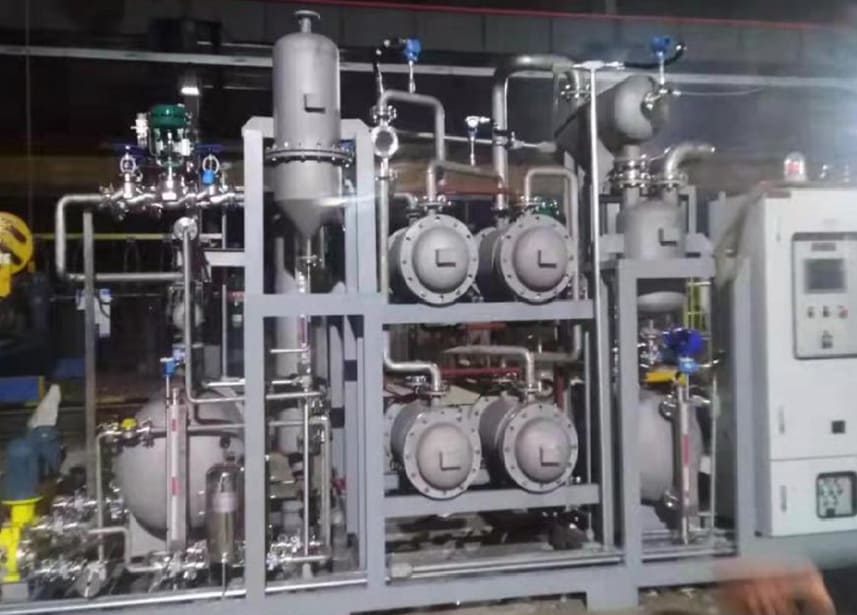

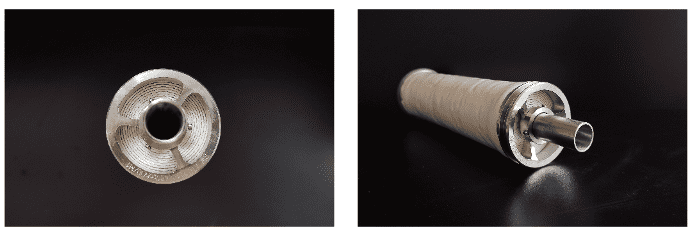

Pervaporation membrane technology process mainly includes a preheater, evaporator, reheater, membrane component, condenser, vacuum system, and PLC system.

Pervaporation membrane dehydration equipment is a specialized device that uses this technology to separate and dehydrate mixtures. The preheater heats the mixture, and it is then fed into the evaporator, where the mixture is vaporized and enters the membrane component.

In the pervaporation membrane separation process, the feed is transported to a filter, heated, and vaporized. It then goes through a gas-liquid separator and enters a series of membrane modules for dehydration. Water molecules selectively pass through the membrane and are collected via a vacuum condensation system. The dehydrated solvent product is condensed and collected in a product tank. The process operates at 60°C-150°C with a pressure of 0-3 kg.

Currently, our company is the only one in China that

independently produces acid-resistant inorganic pervaporation membranes. These membranes can be used in systems with a pH range of 2-8.5 and are applicable in high water content dehydration systems. After deep dehydration, the water content in the solvent can be reduced to below 100 ppm, while maintaining high selectivity for water permeation through the membrane during low water content dehydration.

Damo’s membranes meet diverse dehydration needs, especially

for solvent dehydration in the liquid phase, with a total product recovery rate of over 99%. Our company has extensive experience in integrating membrane separation with other technologies, enabling the separation and purification of complex.

Feedstock: For a 1,500-ton annual ethanol production, reduce water content from 15% to 0.2%.

Membrane Dehydration Performance Indicators:

Deep Dehydration of Organic Solvents

Feedstock: Dichloroethanol feedstock has a water content of approximately 4%, requiring reduction to 0.05% or lower, with an annual production of 150 tons.

Membrane equipment performance indicators:

One chinese company successfully implemented Damo’s PVmembrane technology for their ethanol dehydration project, achieving a production capacity of 50,000 tons/year.

Membrane Dehydration Result:

Low-concentration Organic Waste Liquid Recovery System

Feedstock: Acetonitrile has a water content of approximately 80% and minor impurities. The goal is to reduce water content from 80% to 1% or lower, treating 6,000 tons annually.

Membrane Dehydration Performance

Benzene and Derivative Removal

Feedstock: The hydrogen chloride feedstock contains approximately 10 g/m³ of benzene and chlorobenzene, requiring reduction to below 0.3 g/m³, with a treatment capacity of 60 m³ per hour.

Adsorption Technology Performance

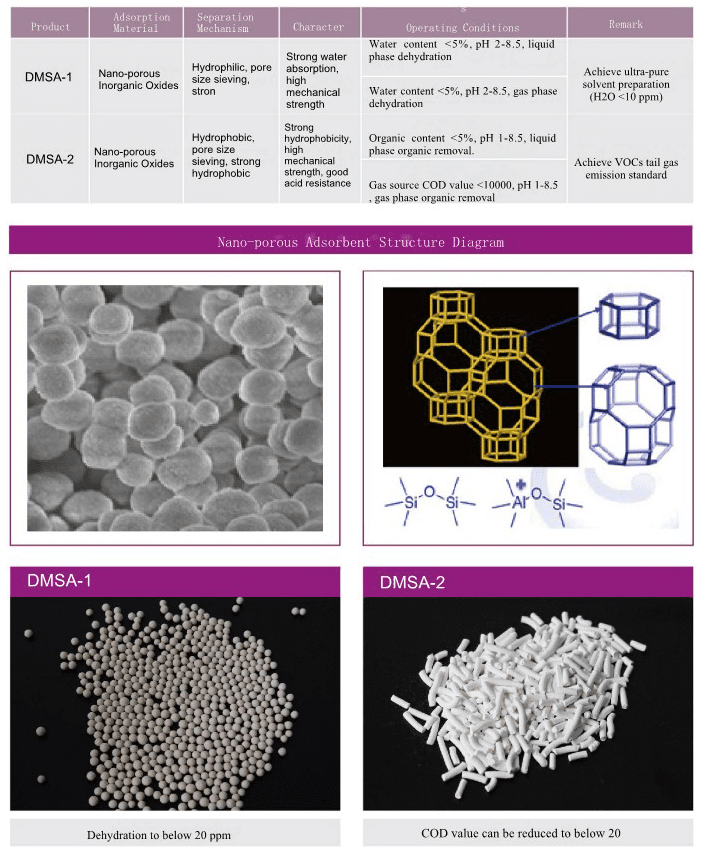

High adsorption efficiency with DMSA-1 reducing water content in solvents to <10 ppm and DMSA-2

lowering COD values in organic wastewater and VOCs

tail gas. Little impact from water content in raw materials

Non-catalytic, non-flammable, safe, and doesn’t produce hazardous waste.

Physically and chemically stable, solvent-resistant, thermally stable, high mechanical strength, and service life >5 years (DMSA-2).

Easy activation/ regeneration, low steam consumption, and low operating costs.

Nano Adsorption Applications

DMSA-1: Dehydration of organic solvents (DMF, acetone, etc.) and deep dehydration below 200 ppm.

DMSA-2: Recovery and utilization of low-concentration organic compounds (solvent wastewater, VOCs tail gas) while achieving

Examples:

DMSA-1: Reduces water content in isopropanol from 500 ppm to around 30 ppm.

DMSA-2: Lowers isopropanol content in water from 3% to around 0.03%.

DMSA-2: Reduces ethyl acetate content in water from 2.5% to below 0.002%.

DMSA-2: Decreases benzene and chlorobenzene in VOCs tail gas from 20g/m to below 5 ppm.

The organic vapor recovery system separates through a dissolution-diffusion mechanism. Organic gas molecules dissolve on the membrane surface, creating a concentration gradient. Due to different diffusion rates, gas molecules migrate from one side of the membrane to the other, finally desorbing and achieving separation for organic matter recovery or removal.

Compared to traditional separation methods, this process is safe, efficient, energy-saving, pollution-free, environmentally friendly, and easy to scale up with continuous operation capabilities.

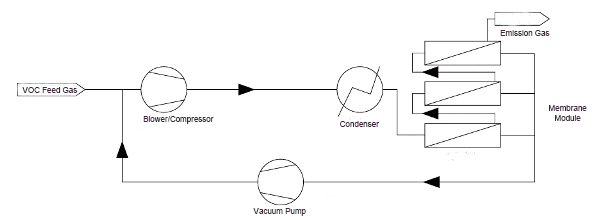

VOC feed gas is transported to a condenser by a fan or compressor

(removing water and high-concentration organics) and enters the membrane module. Organic substances diffuse and dissolve on the Membrane surface, and the permeate side condenses for recovery

High selectivity: VOC components enter the permeate side, while n2/ch4

remains on the residual side, providing high selectivity.

Cost-effective: Higher permeation rates and less membrane usage result in

lower costs and reduced energy consumption.

Simple and flexible: Continuous physical separation process, no need for water or adsorbents, safe operation, easy startup, modular design, and easy

to expand or combine with other processes.

Process improvement in chemical production – recovering individual components from exhaust gas.

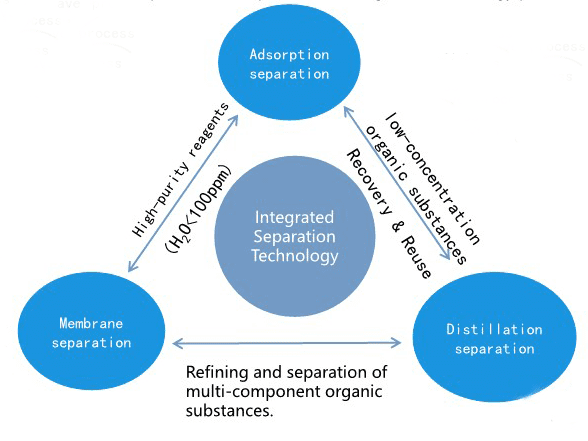

This technology combines adsorption, membrane separation, and

distillation to process complex organic solvent systems and recover substances. It effectively addresses wastewater pollution, enhances efficiency, and provides significant economic value

Our company has developed comprehensive application processes, control systems, and complete equipment in collaboration with leading

institutions.

Chinese Academy of Sciences technical team, continuously bringing technological revolution.

Industry leader

Damo Tech is a global leader in acid-resistant pervaporation membrane products, ensuring top-quality solutions.

Exclusive technology

Unique and innovative technology sets it apart, providing a competitive edge in the market.

Sustainable Separation

Our products contribute to environmentally friendly processes, reducing waste and emissions

Cost-Effective

Damo Tech's solutions help clients save energy, reduce operating costs, and improve overall process efficiency.

Pervaporation membrane technology is an energy-efficient and environmentally friendly separation process that uses selective membranes to separate components in liquid mixtures, often used for sustainable separation applications

Pervaporation membranes work by allowing selective permeation of specific components in a liquid mixture through the membrane, driven by a partial vapor pressure difference across the membrane. The permeate is collected as vapor on the other side and condensed if needed.

Acid-resistant membranes: Damo Tech is a leader in producing acid-resistant pervaporation membranes (pH < 5), utilizing proprietary technology for challenging separation applications. Expertise in complex separations: Damo Tech's membranes are effective in handling complex mixtures, including low-concentration organic solvents, multi-component systems, and azeotropic mixtures.

Pervaporation membranes are used in various industries, such as chemical, pharmaceutical, and environmental sectors, for dehydration of organic solvents, breaking azeotropes, and purification of complex liquid mixtures.

Yes, pervaporation membranes can be tailored to suit specific applications by selecting appropriate membrane materials and optimizing process conditions to achieve the desired separation performance. Consultation with membrane manufacturers is recommended for

Pervaporation membranes offer numerous benefits, including low energy consumption, high selectivity, NO waste generation, and the ability to handle heat-sensitive materials without thermal degradation.

Get in Touch

Damo provides advanced pervaporation systems, hydrophilic and organophilic membranes, and containment modules for organic solvent production/recovery, high-purity reagents, and VOCs in industries like biopharma, new energy, fine chemicals, electronics, food, and environmental protection, utilizing integrated membrane separation, distillation, and adsorption technologies.

If you want to save costs and reduce environmental issues for your business, please contact Damo Tech’s expert team. We will provide you with the best solutions and the most cost-effective approach.

Menu

Advanced pervaporation systems, membranes, and modules for efficient separation processes.

NO.2588, F Building, Sanbei Street, Cixi, Zhejiang, China.

+86 18657634288

he@damopvm.com