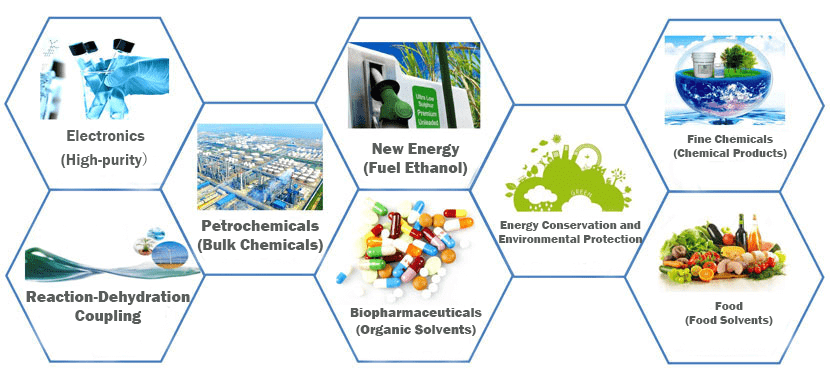

Advanced Solutions for Dehydrating Organic Solvents and Acids in Pharmaceuticals and Fine Chemicals.

Achieve over 50% energy savings compared to traditional distillation methods, ensuring operational efficiency and cost-effectiveness.

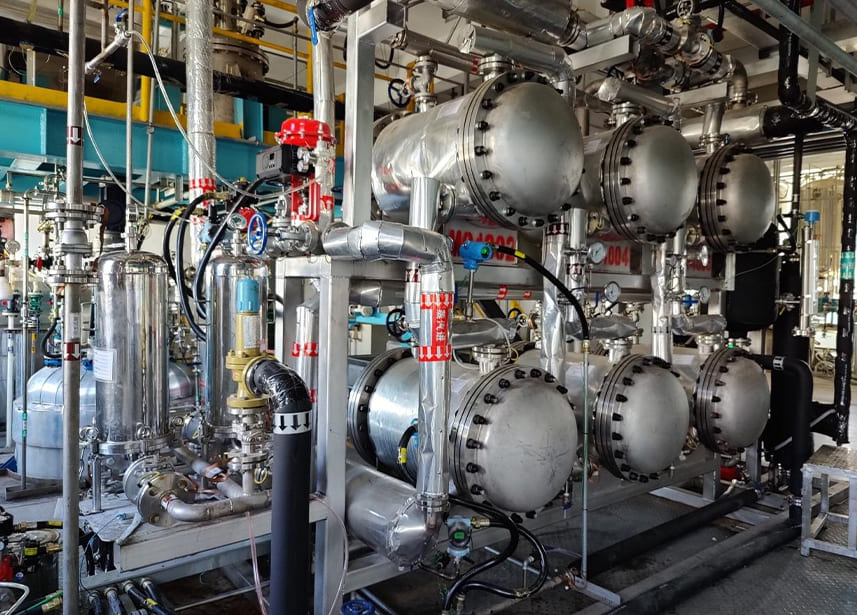

Seamlessly integrate into industrial processes with a scalable and space-saving modular system.

A chemical-free, green separation process perfectly aligned with sustainability goals.

Operates efficiently across a pH range of 2.0 to 8.5, making it ideal for most organic solvents and acids

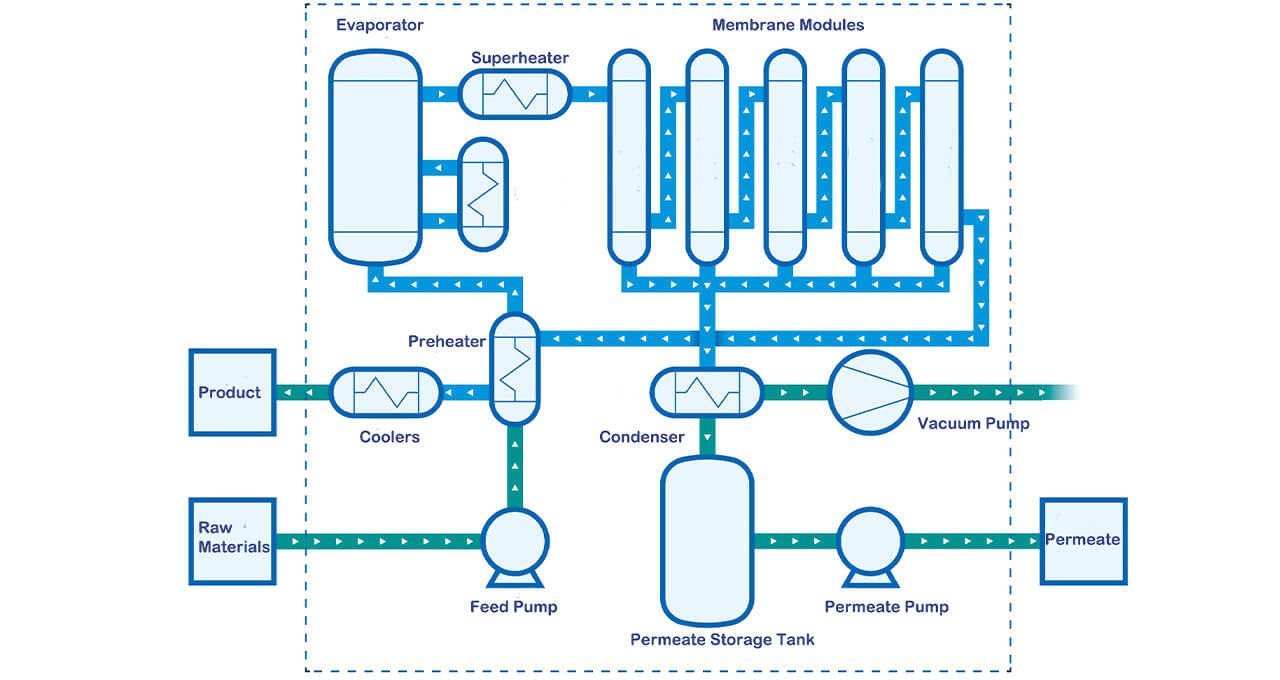

The feed material is pumped into the system and passes through a filter unit, ensuring no solid impurities or particles can damage the membrane. Once filtered, the raw material is preheated using a heat exchanger, which recycles energy from the dehydrated product to improve overall efficiency.

The preheated raw material enters an evaporator, where it is heated to form vapor. This step ensures the mixture reaches the optimal state for separation, typically between 60°C and 150°C, depending on the material type and water content.

The vaporized feed flows into the membrane module system, the heart of the technology. Here’s what happens:

The dry vapor exits the membrane module and enters a cooling system. Using condensers, the vapor is cooled back into a liquid state. This high-purity dehydrated product, now free of excess water, is collected in a storage tank, meeting industrial standards (e.g. water content below 0.5%).

Water molecules that permeate through the membrane are collected via a vacuum condensation system. These water molecules are condensed and discharged into a permeate tank, ensuring proper separation and enabling environmentally sound wastewater management.

The entire process is PLC-controlled for precision and safety. Real-time monitoring of parameters such as temperature, pressure, and flow ensures smooth operation. This level of automation minimizes manual intervention and enhances efficiency.

The process incorporates heat recovery systems, recycling heat from the dehydrated product to preheat the incoming feed. This significantly reduces overall energy consumption, making the system not only efficient but also cost-effective for long-term operations.

Damo’s pervaporation membrane process is a clear step forward for industries requiring high-purity organic solvents and acids while reducing operational costs and environmental impact.

Dehydration of Ethanol: Case Study of Zhongyu Food Co.

Damo’s innovative pervaporation membrane technology was successfully implemented in Zhongyu Food Co.’s anhydrous ethanol production project. This case emphasizes the efficiency, reliability, and scalability of our technology while dehydration in an industrial scale setting.

Project Details:

Key Highlights of the Case:

Acetonitrile Recovery Success: Efficiency Redefined

Damo has collaborated with one pharmaceutical enterprise to apply a high end solution for the acetonitrile recovery project. Employing our PV membrane technique, They managed to minimize water and solvent recovery to the levels never been achieved in the industry.

Project Highlights:

Key Achievements:

Improved Dekhydration Process

Reduced water from 20% to an extraordinary 0.1%. Such a degree of dehydration is essential in most applications requiring a high degree of purity such as pharmaceutical and fine chemical industries.

Custom-Tailored Solution

Damo delivered a bespoke design to match client’s feed composition and production goals. This included optimizing membrane modules and process parameters to ensure seamless integration with their existing operations.

Ethyl Ether Dehydration for Xiamen Kingdomway Vitamin Production

Ethyl ether dehydration was very important to the Xiamen Kingdomway, which is a leader vitamin producing company, so making sure of achieving accurate ether dehydration is the primary task. To solve the Dehydration problem, Damo’s PV membrane technology was selected, which offered and precision and effectiveness in the elimination of water.

Project Details:

Solution Delivered:

Precision for Critical Applications

The desired end product had a stringent requirement with regards to water content (from 2% to 0.1%), it was necessary to meet very stringent standards. The use of Damo’s PV membrane technology made sure the dehydration process was consistent and accurately controlled, which is critical in the production of high-purity ether in vitamin synthesis.

Compact and Modular Design

With limited space in the Kingdomway facility, Damo designed a compact, skid-mounted system that seamlessly integrated into their existing process. This modular design enabled efficient installation and minimized disruption to ongoing operations.

Enhanced Operational Stability

The dehydration process was performed continuously and hence provided stable performance with minimal downtime. This allowed Kingdomway to maintain its production schedule.

Changlian New Material’s Success with Damo membrane technology to dehydration of Isopropanol.

In order to meet their advanced materials production the construction of Hunan Changlian New Material was developing a process to manufacture isopropanol (IPA) of over 99% purity. With a reduction of water content from 10% to 0.1%, Damo’s PV membrane technology was employed to provide an appropriate solution that ensured quality and effectiveness in operations.

Project Details

Unique Challenges and Solutions

Dealing with Complicated Feed Composition

The IPA feed presented unique challenges due to its relatively high water content and strict purity demands. Damo implemented a multi-stage dehydration process using advanced PV membranes, ensuring consistent water removal while maintaining IPA’s chemical integrity.

Long-Term Reliability and Durability

The system developed by Damo is highly durable and requires minimal maintenance due to its continuous production schedule. It is designed to function efficiently for up to 5 years if maintained properly.

Compact Excellence: DMF Dehydration for Jiangsu Chemical Plant

A leading chemical plant in Jiangsu managed to efficiently dehydrate dimethylformamide (DMF) through Damo’s reliable solution when they sought to bring down its water content from 40% to 5000 ppm. The project showcases the ability of small high scale technology to resolve large scale problems.

Project Details:

What Makes This Project Unique?

Ultra-Compact System Design

Damo presented a 10 cube meter skid-mounted solution in contrast to most dehydration systems which are bulky and require high infrastructure space. This compact system integrated well in the existing plant thus major modifications were not required.

Plug-and-Play Installation

The pre-assembly and testing of the modular system before delivery, quick on site installation was possible. This eliminated significantly downtimes and assisted the Jiangsu plant to reach full operational capacity in a short period of time

This mini unit is sufficiently mobile and is useful for laboratory and limited field application, thus seeing the technology in action is safe and easy.

Key Features

Operational Requirements:

Pricing:

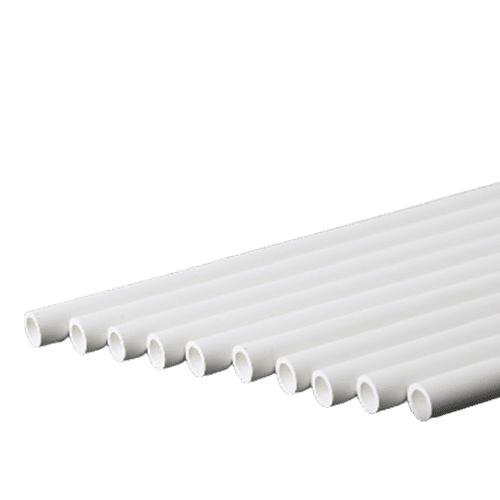

Efficient Damo pervaporation membrane for organic solvents, high-purity reagents & VOC

separation within pH 2-8.5 optimal dehydration performance.

Strong surface hydrophilicity, solvent water content 20 wt%, solvent pH 6.5 ~8.5

Not suitable for acidic or alkaline systems, vapor phase dehydration.

High surface hydrophilicity, deep solvent dehydration (water <100 pm)

Solvent pH 58.5, vapor phase/liquid phase dehydration

Suitable for acidic (organic acid) systems, achieving deep solvent dehydration (water <100 ppm). Can reach a minimum of 50ppm.

Water content <5%, pH 6.5 ~8.5, liquid phase dehydration, vapor phase dehydration, achieving

ultra-pure solvent preparation.

Organic content <5%, pH 1~8.5, vapor phase, liquid phase organic removal, achieving VOCs tail

gas compliant emissions.

Organic molecules preferentially dissolve and diffuse through the membrane layer, achieving

separation from air or nitrogen gas.

At Damo, we understand the challenges industries face with solvent dehydration and recovery. Our advanced PV membrane technology is engineered to deliver efficiency, reliability, and sustainability. Whether it’s ethanol, acetonitrile, DMF, or other solvents, we offer customized systems designed to meet your exact requirements for purity, capacity, and operational efficiency, and ensures precise dehydration with minimal energy consumption, helping you save costs while maintaining top-quality results.

From compact lab-scale units for testing to large-scale industrial setups, Damo provides systems that fit seamlessly into your operations, with scalability to grow with your business.

Reduce energy consumption, eliminate chemical additives, and minimize waste with our eco-friendly solutions that align with global sustainability goals.

From initial consultations to installation and after-sales service, our team of experts is dedicated to ensuring your success with comprehensive technical guidance and support.

Damo is more than just a technology provider – we’re your partner in achieving greater efficiency, sustainability, and profitability.

Menu

Advanced pervaporation systems, membranes, and modules for efficient separation processes.

NO.2588, F Building, Sanbei Street, Cixi, Zhejiang, China.

+86 18657634288

he@damopvm.com