In the chemical industry, dehydration of isopropanol is a critical process. The traditional methods often consume a lot of energy and have a significant environmental impact. But what if there was a more efficient, eco-friendly solution? Enter Damo Membrane, a game-changer in the field of isopropanol dehydration.

Damo Membrane: A Sustainable Solution

Damo Membrane, developed by Damo Technology, is a high-efficiency pervaporation membrane designed for organic solvents, high-purity reagents, and VOCs purification and recovery. It’s a sustainable separation solution that not only meets the industry’s needs but also contributes to environmental protection and sustainable development.

Why Choose Damo Membrane for 45000 Liter Isopropanol Dehydration?

Energy Efficiency

Damo Membrane operates under mild conditions, without phase transitions, making the process highly energy-efficient. This can lead to significant savings in energy costs for your business.

Environmental Friendliness

Unlike traditional methods, Damo Membrane does not produce secondary pollution. It operates at lower temperatures, making it more environmentally friendly. By choosing Damo Membrane, you’re not only optimizing your process but also contributing to a greener planet.

Cost Savings

Damo Membrane offers a high product recovery rate of over 99%, with low product concentration in the permeate. This means less waste and more savings for your business. Moreover, Damo Membrane is easy to scale up and integrate with other processes, making it a cost-effective solution for isopropanol dehydration.

Customization

Damo Technology provides customized solutions tailored to your unique needs. Whether you’re a technical director, workshop manager, or procurement manager, Damo Technology is committed to providing you with the best solution that fits your requirements.

Damo Membrane: Dehydrating 45k Litres of Isopropanol

Overview of Organic Solvent Purification

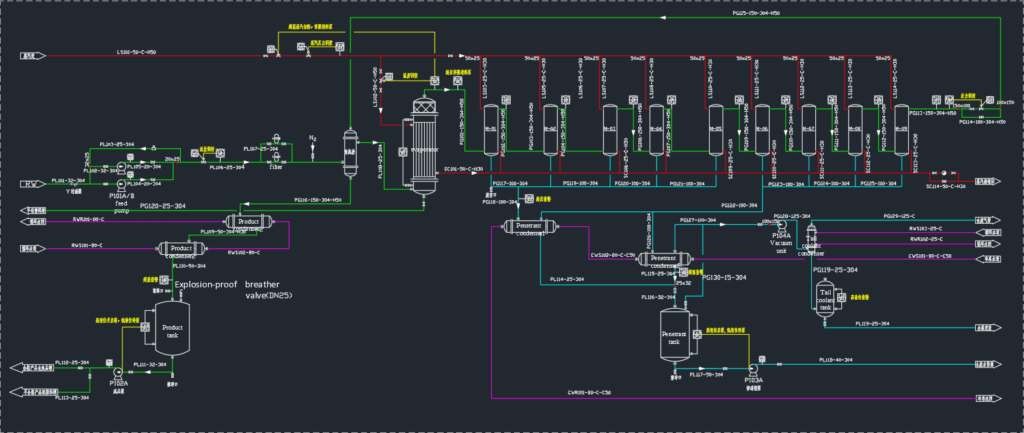

The Damo PV Membrane system is designed with a focus on efficiency and sustainability. The process begins with the raw material, an IPA solution, being transported to a filter by a pump. This filter, with a pore size of around 0.1 μm, ensures that any impurities are removed before the solution moves on to the next stage.

Once filtered, the raw material is preheated in a heat exchanger. This step is crucial as it allows for the recycling of heat from the dehydrated product, contributing to the overall energy efficiency of the system. The preheated material is then vaporized in an evaporator using steam.

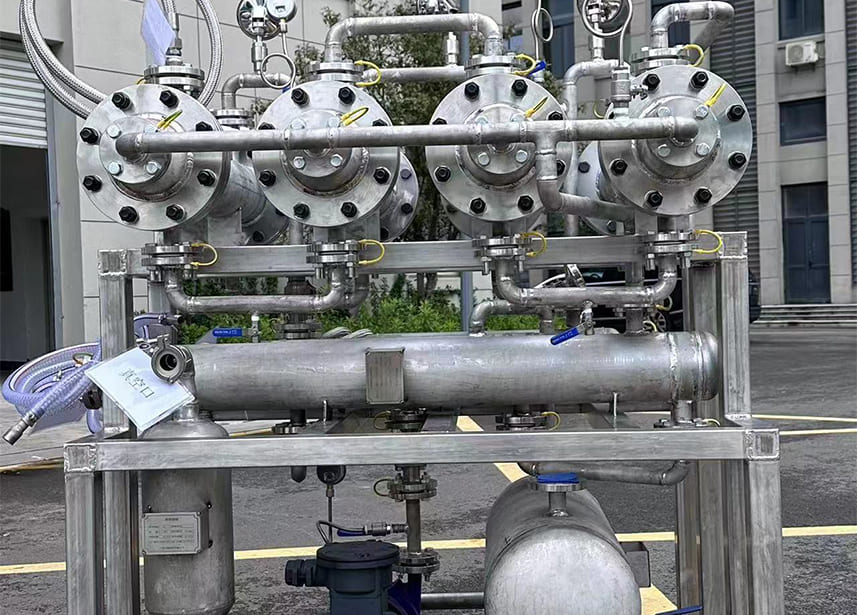

The vaporized material then flows into the membrane separator for the dehydration process. The system is equipped with nine membrane separators, which are arranged in series. The water molecules selectively permeate through the membrane under the influence of a pressure difference and are collected in a storage tank by a cooled condenser. This water is then transported to the next process by a pump.

The product produced by the membrane is cooled and collected in a separate storage tank. This product is then transported to the next process by a pump. The entire process is controlled automatically and monitored online with PLC and HMI, ensuring safety and simplicity.

The installation construction period is efficient, with commissioning conditions available within 80 days after the contract takes effect. The equipment footprint is compact, with dimensions of length * width * height =10.5m2.0m3.6m. This compact design allows for easy installation and minimal space requirements.

The Damo PV Membrane system offers significant advantages over traditional distillation methods. It is efficient and energy-saving, with water content effectively decreased to less than 0.05%, and commonly consumes less than 0.5 tons of steam for 1 ton of solvent solution. It is also environmentally friendly, as there is no need to introduce other components for azeotropic dehydration systems.

Damo Membrane Solution for IPA Dehydration

Information for Raw Materials

| Total Mass Rate: 1428.9 kg/h | ||

| Composite | Isopropanol(wt%) | 93.45 |

| H2O(wt%) | 5.64 | |

| 13BD(wt%) | 0.03 | |

| SULFOLENE(wt%) | 0.03 | |

| SULFOLENE(wt%) | 0.88 | |

| Product | H2O(wt%) | ≤0.19 |

Operation Parameters for Equipment

| 1 | Feed Temperature(℃) | 100~125 |

| 2 | Feed Pressure(MPa) | 0.1~0.3 |

| 3 | Product Temperature (℃) | <40 |

| 4 | Vacuum degree | ≤-98kPa |

| 5 | Equipment explosion-proof level | dIIBT4 |

| 6 | Operation mode | Round the clock |

Feed Conditions

The pH of raw material is in the range of 6.5 to 8.5. The conductivity of raw material is less than 5 μS/cm. In addition, without of polymer, salts, saccharides, solid marticles, acidity, alkalinity etc, which will damage permeation membrane in the raw material.

PV Membrane Technology Introduction

Inorganic pervaporation membrane can effectively separate water from organic solvents by surface-adsorption and molecular-sieving mechanization. Because the polarity of water is greater than the most of organic solvents and molecular size of water (0.29 nm) is smaller than the most of organic solvents. In this project, the pore size of permeation membrane(0.4 nm)is between the molecular size of water and isopropanol (IPA).

Thus, the water can be effectively removed from IPA solution. Compared to distillation technology, the advantages of membrane technology are significant. The advantages are as follows.

1)Efficient and energy-saving: water can effectively decrease to less than 0.05%, and commonly consumes less than 0.5 tons of steam for 1 ton of solvent solution.

2)Environmentally friendly: there is no need to introduce other component for azeotropic dehydration system.

3)Safe and simple: the process is automatic control and online monitoring with PLC and HMI.

4)Simple installation: the equipment is modular design with small footprint.

Technical Process Description

The raw material (IPA solution) is quantitatively transported to the filter (pore size is around 0.1 μm) by a pump. And then, the filtrated raw material is preheated in a heat exchanger to recycle heat from dehydrated product. Subsequently, the material is vaporized in the evaporator by steam. Finally, the vaporized material flows into the membrane separator for dehydration.

In this project, the equipment has nine membrane separators which vessel in series. The water molecules selectively permeate through the membrane under pressure difference and collect in a storage tank by the cooled condenser. The collected water is then transported to the next process by a pump. The product produced by the membrane is cooled and collected in a storage tank and transported to the next process by a pump.

Installation Construction Period

Commissioning conditions are available within 80 days after the contract takes effect

Equipment Footprint

Length * width * height =10.5m*2.0m*3.6m

List of Major Equipment

| No. | Device name | material | unit | quantity | Model and description |

| 1 | Membrane module | S304 | set | 9 | 25m2/set |

| 2 | Membrane | ceramic | m2 | 225 | Φ12*800(length) |

| 3 | Sealing ring | fluorine | set | 30600 | Φ11*3.25 |

| 4 | feed pump | Overflow parts S304 | set | 2 | 3m3/h,H>30m,explosion-proof motor |

| 5 | Product pump | Overflow parts S304 | set | 1 | 3m3/h,H>30m,explosion-proof motor |

| 6 | Tail-cooled pump | Overflow parts S304 | set | 1 | 3m3/h,H>30m,explosion-proof motor |

| 7 | Penetrant pump | Overflow parts S304 | set | 1 | 3m3/h,H>18m,explosion-proof motor |

| 8 | evaporator | S304 | set | 1 | A=3.5m2 |

| 9 | preheater | S304 | set | 1 | A=1.5m2 |

| 10 | filter | Overflow parts S304 | set | 2 | Filtration accuracy (0.1μm) |

| 11 | Penetrant condenser | S304 | set | 2 | A1=5m2,A2=5m2 |

| 12 | Product condenser | S304 | set | 2 | A1=5m2,A2=5m2 |

| 13 | Penetrant tank | S304 | set | 1 | V=150L |

| 14 | Product tank | S304 | set | 1 | V=2000L |

| 15 | Tail coolant tank | S304 | set | 1 | V=150L |

| 16 | Tail coolant condenser | S304 | set | 1 | A=1m2 |

| 17 | Vacuum unit | Multiple | set | 1 | 150L/S (Roots pump)+70L/S (Screw pump) |

| 18 | Back pressure valve | Overflow parts S304 | set | 3 | PTFE |

| 19 | Positive pressure explosion-proof control cabinet | PLC | set | 1 | Siemens |

| HMI | Siemens,Nine inches | ||||

| Low-voltage electrical apparatus | Schneider,A batch | ||||

| Control program | A set | ||||

| System integration | A set | ||||

| 20 | regulating valve | Overflow parts S304 | set | 4 | |

| 21 | Liquid level transmitter | Overflow parts 316L | set | 4 | 4~20mA,remote transmission, flameproof |

| 22 | pressure transmitter | Overflow parts 316L | set | 3 | 0~1MPa,4~20mA,remote transmission and display, flameproof |

| 23 | Temperature transmitter | Overflow parts S304 | set | 5 | 0~200℃,4~20mA,remote transmission and display, flameproof |

| 24 | Vacuum transmitter | Overflow parts 316L | set | 1 | -0.1~0.1MPa,4~20mA,remote transmission and display, flameproof |

| 25 | Pneumatic shut-off valve | Overflow parts S304 | set | 1 | 4~20mA |

| 26 | Explosion-proof breather valve | Overflow parts S304 | set | 1 | |

| 27 | Bimetallic thermometer | Overflow parts S304 | set | 7 | 0~200℃ |

| 28 | flowmeter | Overflow parts S304 | set | 1 | |

| 29 | Pipes, valves | S304/ Carbon steel | batch | 1 | PN16 |

| 30 | steam hydrophobic valve | Carbon steel | set | 2 | |

| 31 | Framework and platform | Carbon steel | set | 1 | |

| 32 | Auxiliary materials and processing | set | 1 | ||

| 33 | Design, transportation, packaging | set | 1 | ||

| 34 | Training and debugging | set | 1 | ||

| 35 | heat preservation | set | 1 |

Technological Advantages

The Acid-Resistant Nanopore Dehydration Membrane developed by Damo PV Membrane is a technological marvel. It can endure a pH range of 3~8.5 (acidic systems do not contain inorganic acid radicals), has good hydrothermal stability, high separation performance, low organic content in the permeate, and can achieve solvent dehydration under gas or liquid phase conditions.

Its operational energy consumption is low, the process is simple, and it saves over 80% of treatment energy compared to traditional distillation systems, with no other wastewater or waste gas generated.

After-Sales Service and Personnel Training

1)Regular spare parts that are urgently needed will be delivered to the site within 1~3 days.

2)Regular telephone follow-up of equipment operation in the first 1~3 months after equipment operation.

3)Domestic service can be provided within 24 hours, and in case of major problems or when necessary, we will be at the site within 24 hours in the province/48 hours outside the province to assist in solving the problems. Abroad depending on circumstances and visa issues.

4)Spare parts and operating consumables are supplied at the most favorable market price for a long term.

Conclusion

In conclusion, Damo PV Membrane’s advanced pervaporation systems, hydrophilic and organophilic membranes, and containment modules for organic solvent production/recovery, high-purity reagents, and VOCs in industries like biopharma, new energy, fine chemicals, electronics, food, and environmental protection, utilizing integrated membrane separation, distillation, and adsorption technologies, offer a cost-effective and environmentally friendly solution for Isopropanol (IPA) dehydration.