In today’s fast-paced and environmentally conscious world, companies across various industries are constantly seeking innovative solutions to improve their processes and reduce their ecological footprint. Damo’s pervaporation membrane technology for ethanol dehydration is a groundbreaking solution that addresses these concerns while enhancing efficiency and product quality.

In this blog post, we will discuss how Damo’s cutting-edge technology is revolutionizing dehydration in industries such as pharmaceuticals, new energy, fine chemicals, electronics, food, and environmental protection.

Damo’s Pervaporation Membrane Technology: A Game-Changer for Ethanol Dehydration

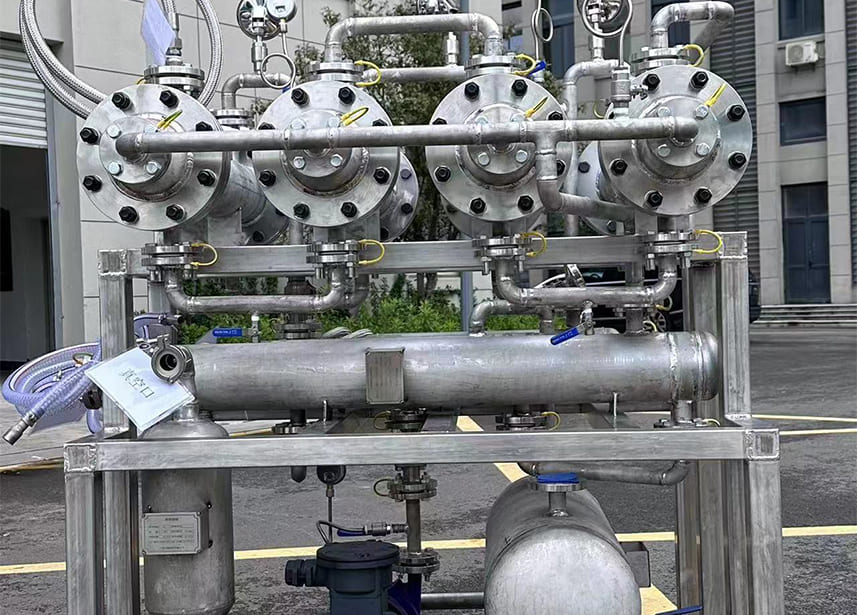

Shandong-based company successfully implemented Damo’s PVmembrane technology for their ethanol dehydration project, achieving a production capacity of 50,000 tons/year. By using liquid-phase equipment, the company was able to dehydrate ethanol from 5% to 1%. This outstanding performance is attributed to Damo’s proprietary PV membrane, which excels in solvent deep dehydration (water content <100 ppm).

Wide Range of Applications

Damo’s pervaporation membrane technology is versatile and can be applied to various industries, including pharmaceuticals, new energy, fine chemicals, electronics, food, and environmental protection. It is particularly effective for the production and recovery of organic solvents (such as alcohols and esters), high-purity reagents (such as isopropanol and dimethyl carbonate), and VOCs (such as benzene and acetone).

Integration with Other Separation Technologies

Damo’s rich experience in membrane separation and integration with other technologies enables them to provide comprehensive solutions for complex material separation and purification processes. By combining membrane separation with distillation and adsorption techniques, Damo can deliver integrated separation technologies that cater to specific industry requirements.

High Product Recovery Rate and Energy Efficiency

Damo’s pervaporation membrane technology offers an impressive product recovery rate of over 99%, making it a highly efficient solution for various dehydration needs. Furthermore, its ability to operate in the liquid phase enables solvent dehydration without the need for additional energy-intensive processes. As a result, Damo’s technology significantly reduces energy consumption compared to conventional methods.

Minimal Environmental Impact

One of the key advantages of Damo’s pervaporation membrane technology is its environmentally friendly nature. Unlike traditional dehydration methods that may require the introduction of a third component, Damo’s technology avoids secondary pollution and allows for easier scaling and integration with other processes. This ensures that the technology not only meets the needs of various industries but also contributes to environmental sustainability.

Cost-Effectiveness and Ease of Maintenance

Damo’s pervaporation membrane technology offers cost-effective solutions for industries looking to optimize their dehydration processes. The modular design of the technology allows for easy installation and maintenance, requiring minimal infrastructure investments. The reduced energy consumption and high product recovery rates also contribute to the overall cost savings for companies adopting this advanced technology.

Conclusion

Damo’s pervaporation membrane technology is a game-changer for companies looking to improve their dehydration processes while reducing their environmental impact. Its adaptability to various industries, high product recovery rate, energy-efficient operation, minimal environmental impact, and cost-effective nature make it an ideal solution for businesses seeking to optimize their operations and contribute to a sustainable future.

By choosing Damo’s cutting-edge technology, you can expect to see tangible improvements in efficiency, product quality, and cost savings while making a positive impact on the environment. Embrace the future of dehydration with Damo’s pervaporation membrane technology and elevate your business to new heights today.