Are you facing challenges with fuel ethanol dehydration? Discover how Damo’s innovative PV membrane technology helped a factory in Shandong, China achieve a breakthrough in production capacity and dehydration efficiency.

Damo’s PV membrane technology is a highly efficient separation technique that enables selective molecular separation. By using inorganic membranes with pore sizes between water and ethanol molecules, this technology effectively separates water from organic solvent mixtures, resulting in ultra-low water content in the final product.

Learn more about the impressive performance of Damo’s technology in China’s largest fuel ethanol dehydration project and how it can address your own dehydration needs.

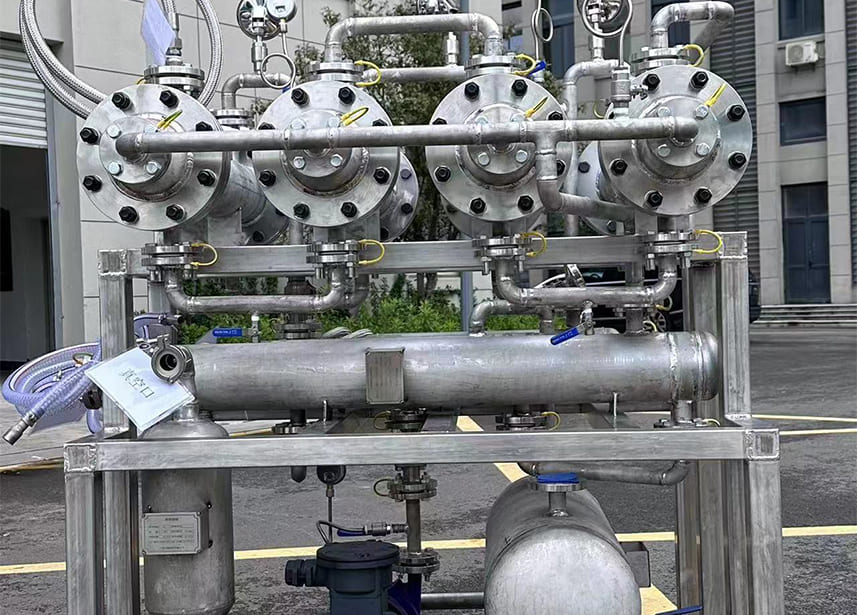

The Impressive Scale of the Project

The Shandong food factory’s fuel ethanol dehydration project is a significant feat in the Chinese fuel ethanol industry. With an annual production capacity of 60,000 tons, it is the largest project of its kind in China. The scale of the project highlights Damo Technology’s capability to deliver reliable and innovative solutions for large-scale production processes.factory’s fuel ethanol dehydration project is a significant feat in the Chinese fuel ethanol industry. With an annual production capacity of 60,000 tons, it is the largest project of its kind in China.

Damo’s pervaporation membrane technology played a crucial role in the project’s success. Starting with 6% water content, the technology was able to dehydrate the ethanol to as low as 50 ppm, which significantly surpassed the initial target of 300 ppm. This impressive result demonstrates the efficiency and reliability of Damo’s membrane technology in the fuel ethanol dehydration process. With Damo’s solution, the Shandong food factory achieved a high-purity fuel ethanol product, ensuring optimal performance in various fuel applications.

Advantages of Damo’s PV Membrane Technology

Energy Efficiency

Damo’s technology requires less energy compared to traditional distillation and adsorption techniques, offering potential energy savings of 30-50% or more.

Environmental Friendliness: The technology does not require the introduction of a third component, and the permeate can be recycled and reused, reducing waste and environmental impact.

Safety and Simplicity

The system is automatically controlled and monitored through PLC and HMI interfaces, ensuring a high level of automation and safety.

Compact Design

The modular design of Damo’s equipment minimizes space requirements and simplifies installation, maintenance, and operation.

Addressing Customer Pain Points

Damo’s pervaporation membrane technology has proven its worth in China’s largest fuel ethanol dehydration project, showcasing its ability to overcome industry challenges and satisfy customer needs. The technology’s energy efficiency, environmental friendliness, safety, and compact design make it a reliable solution for companies seeking efficient fuel ethanol dehydration methods.

In conclusion, Damo’s PV membrane separation solution offers an efficient and eco-friendly solution for fuel ethanol dehydration, as demonstrated by its impressive performance in China’s largest project of its kind. By adopting this innovative technology, companies can improve their production capacity, dehydration efficiency, and environmental impact, effectively addressing common pain points in the industry.