Getting the water out of isopropanol, which is really important for industries like pharmaceuticals, biotechnology, and chemical manufacturing, can be a tricky task. The tricky part is trying to dry out the isopropanol effectively without messing up its quality or hurting our environment. That’s where the Damo PV Membrane steps in. It’s a breakthrough solution that boldly tackles these obstacles. And the best part? It’s a method that’s both kind to the environment and easy on your budget.

Understanding the Challenge: Isopropanol Dehydration

Isopropanol is another name for isopropyl alcohol or what we often call rubbing alcohol. This is a super handy solvent that we use in lots of different ways in the industry. But, just like many similar solvents, isopropanol often has some water in it that we need to take out so it can do its job properly. The usual ways of doing this can use a lot of energy, cost quite a bit, and can also be a bit mean to our environment.

The Damo PV Membrane Solution

Damo PV Membrane offers a groundbreaking solution for isopropanol dehydration. Utilizing advanced pervaporation technology, Damo’s membranes can efficiently separate water from isopropanol, resulting in a highly pure product.

Pervaporation is a process where a liquid mixture is passed through a membrane, allowing selective permeation of specific components. When we’re dealing with getting the water out of isopropanol, we find that water molecules can move through a special membrane more easily than isopropanol molecules can, which helps us separate the two.

Why Damo PV Membrane?

Damo PV Membrane stands out for several reasons:

High Efficiency

Damo’s Pervaporation Dehydration Membrane boasts a high separation efficiency with a product yield of over 99%. This means that almost all the isopropanol fed into the system is recovered, significantly reducing waste.

Sustainability

Damo PV Membrane operates at lower temperatures compared to traditional dehydration methods, making it more energy-efficient and environmentally friendly. Moreover, the process does not produce secondary pollution, further enhancing its eco-friendliness.

Cost-Effectiveness

By reducing energy consumption and waste, Damo PV Membrane can help businesses save on operating costs. A great plus of this technology is that it’s a breeze to scale up and it dovetails nicely with other stuff we’re already doing. This makes it a super handy choice for businesses, no matter how big or small they are.

Versatility

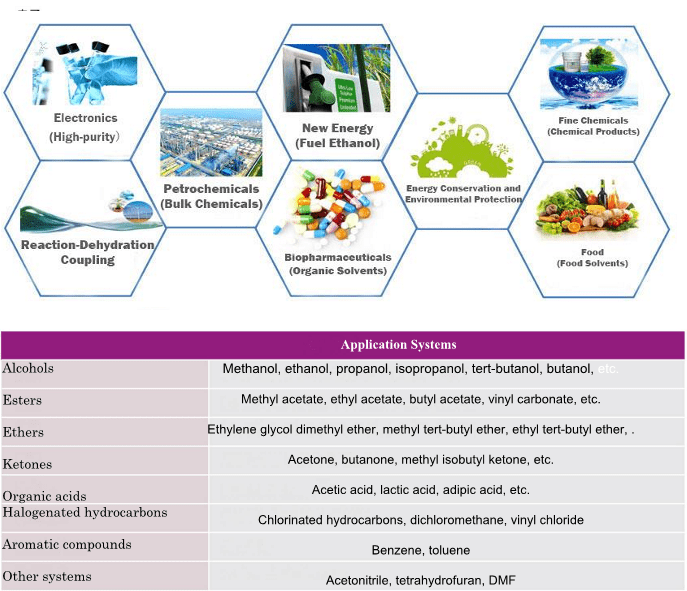

The Damo PV Membrane is made to deal with a broad pH range, between 2 and 8.5, which means it can be used for all sorts of tasks. It can effectively dehydrate organic solvents, even when the solvent undergoes chemical changes after heating, without compromising membrane performance.

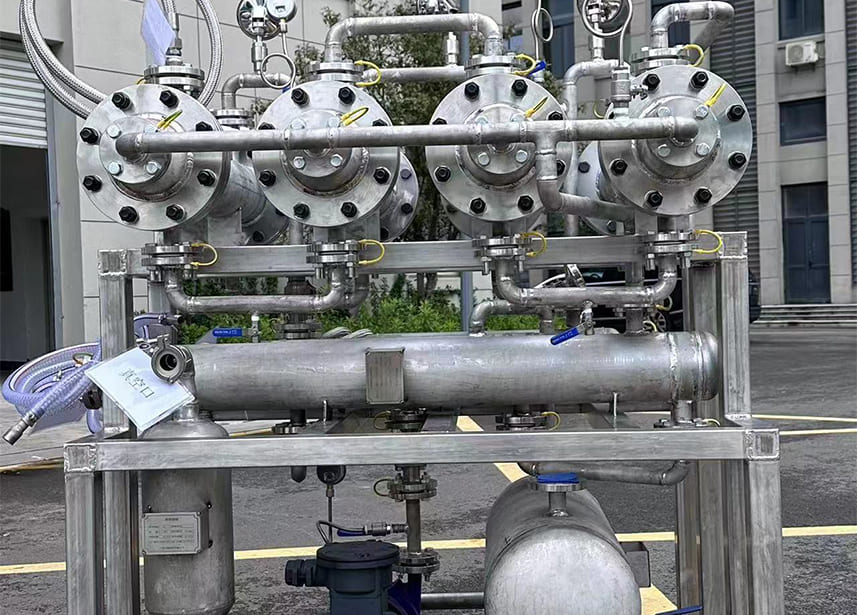

Damo PV Membrane in Action

Damo’s Pervaporation Dehydration Membrane operates in a unique way. The water-containing solvent is preheated and vaporized before entering the membrane module. We keep a vacuum on the other side of the membrane, which helps us create a low-pressure environment. Water molecules pass through the membrane more easily, driven by the pressure difference, which removes water from the solvent. This results in a dehydrated organic solvent product at the outlet, while the components on the other side of the membrane are condensed and sent to wastewater treatment.

Damo PV Membrane: A Game-Changer in Various Industries

Damo PV Membrane is not just limited to the pharmaceutical, biotechnology, and chemical manufacturing industries. This technology isn’t just for one or two industries. It’s used in many areas, like new energy, petrochemicals, coal chemicals, biopharmaceuticals, fine chemicals, electronics, food, environmental protection, and more. The company has developed comprehensive application processes, control systems, and complete equipment in collaboration with leading institutions.

Conclusion

In a world where sustainability and efficiency are paramount, Damo PV Membrane offers a promising solution for isopropanol dehydration. By combining high efficiency, sustainability, cost-effectiveness, and versatility, Damo PV Membrane is set to revolutionize the way industries approach isopropanol dehydration.