In the chemical industry, the demand for efficient, environmentally friendly, and adaptable solutions is on the rise. Damo’s PV membrane separation solution stands out as a game-changer for dehydration processes in various applications. In this blog post, we will explore how Damo’s innovative technology has significantly improved ethyl acetate dehydration in a Zhejiang-based company.

Success Story: Zhejiang Company’s Ethyl Acetate Dehydration Project

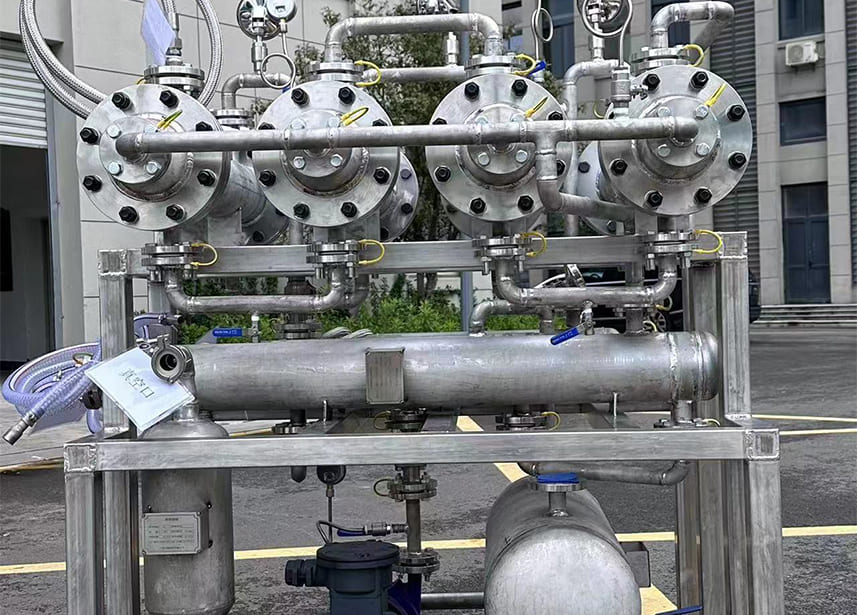

The Zhejiang company applied Damo’s separation solution in their ethyl acetate vapor-phase dehydration project, with an annual production capacity of 1,500 tons. The water content in the ethyl acetate was reduced from 3.5% to 0.1%, showcasing the effectiveness of Damo’s technology.

Wide Range of Applications

Damo’s products have been successfully applied in various fields, such as azeotropic organic solvent dehydration, deep organic solvent dehydration, low-concentration organic solvent recovery, binary and higher mixture organic solvent separation and refinement, and the removal of benzene and its derivatives. These diverse applications have provided Damo with extensive project experience.

Acid Resistance: A Unique Advantage

Damo is the only international company capable of independently producing acid-resistant inorganic pervaporation membrane products. These membranes can be used in systems with a pH of 2 to 8.5 and are suitable for high water content dehydration systems. After deep dehydration, the water content in the solvent can be reduced to less than 100 ppm, while the selectivity for water permeation remains high even at low water content.

Liquid-phase Dehydration: Meeting Diverse Needs

Damo’s technology can satisfy various dehydration requirements, particularly liquid-phase solvent dehydration, with product recovery rates reaching over 99%. The company has rich experience integrating membrane separation with other technologies, enabling precise separation and refinement of complex liquid mixtures.

Pervaporation Membrane Separation Technology: A Pollution-Free Solution

This innovative separation technology is based on the varying solubility and diffusion rates of different components within the solvent in the membrane separation layer. The separation process is not affected by azeotropic systems and does not require the addition of a third reagent, resulting in no secondary pollution. Moreover, the process is easily scalable and can be coupled with other processes.

Conclusion

Damo’s solution is revolutionizing the chemical industry by offering efficient, environmentally friendly, and adaptable dehydration solutions. The successful application in the Zhejiang company’s ethyl acetate dehydration project demonstrates the potential and versatility of this cutting-edge technology.

With its extensive range of applications, acid resistance, liquid-phase dehydration capabilities, and pollution-free separation process, Damo’s technology is poised to redefine dehydration in the chemical industry. Embrace the future of dehydration with Damo’s PV separation solution and take your operations to new heights today.