Ethanol dehydration is a critical process in various industries, particularly those that use organic solvents. The process involves the removal of water from ethanol, often resulting in a product with a water content of less than 0.005%. This high level of purity is essential for many applications, including the production of biofuels, pharmaceuticals, and various chemical processes.

What is Ethanol Dehydration?

Ethanol dehydration is a chemical process that involves the removal of water from ethanol. The most common reaction involved in this process is the conversion of ethanol (CH_3CH_2OH) to ethylene (C_2H_4) and water (H_2O). This reaction is typically facilitated by a catalyst and occurs under high temperatures.

Methods of Ethanol Dehydration

There are several methods of ethanol dehydration, each with its own advantages and disadvantages. The choice of method often depends on the specific requirements of the application, including the desired level of purity and the available resources.

Pervaporation Membrane Separation

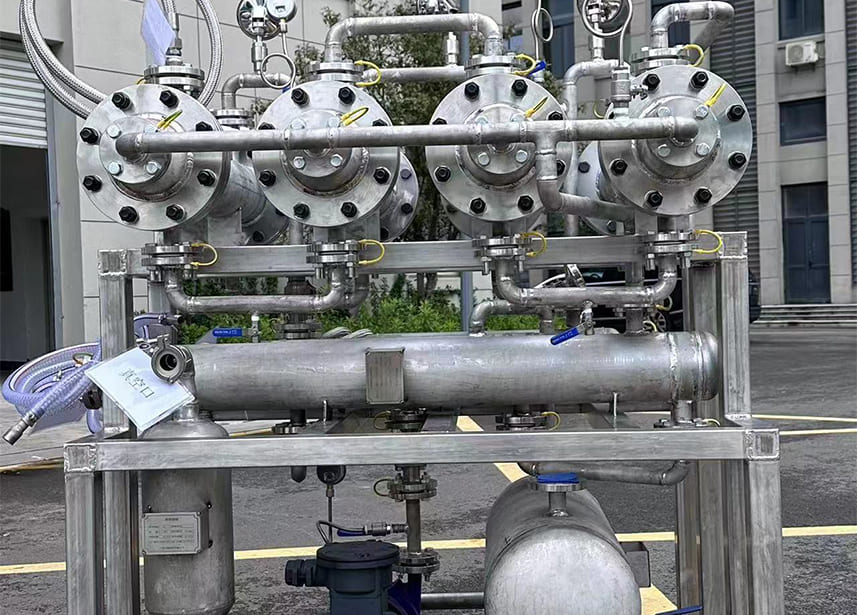

One of the most effective methods of ethanol dehydration is pervaporation membrane separation. This technology uses a selective membrane to separate the water from the ethanol. The process works by creating a pressure difference across the membrane, which drives the water molecules through the membrane, leaving behind the dehydrated ethanol.

Damo PV Membrane, a leading provider of advanced separation and purification technologies, offers high-performance pervaporation membranes for ethanol dehydration. Their Pervaporation Dehydration Membrane (DMMST-2/3) boasts a high separation efficiency, with a product yield of over 99%, and a low product concentration in the permeate, which is less than 1%.

Adsorption

Adsorption is another common method of ethanol dehydration. This process involves the use of an adsorbent material, such as a molecular sieve, to selectively adsorb the water molecules from the ethanol. The adsorbent material is then regenerated, typically by heating, to remove the adsorbed water and prepare it for the next cycle of dehydration.

Benefits of 99.995% Ethanol Dehydration

The high level of purity achieved through ethanol dehydration offers several benefits. For one, it improves the efficiency of various chemical processes, as the presence of water can often interfere with chemical reactions. Additionally, it allows for the production of high-purity ethanol, which is essential for applications such as biofuel production and pharmaceutical manufacturing.

Moreover, using advanced technologies like pervaporation membrane separation for ethanol dehydration can offer additional benefits. For instance, this method is highly energy-efficient and environmentally friendly, as it operates at lower temperatures and does not produce secondary pollution. It is also easy to scale up and integrate with other processes, making it an attractive option for many industries.

Future Prospects of Ethanol Dehydration

With the increasing demand for high-purity ethanol in various industries, the importance of efficient and effective ethanol dehydration methods is set to grow. Advances in technology, such as the development of more efficient and selective membranes for pervaporation, are likely to drive this growth.

Furthermore, as industries continue to seek more sustainable and environmentally friendly processes, methods like pervaporation membrane separation, which offer high efficiency and low environmental impact, are likely to become increasingly popular.

Conclusion

Ethanol dehydration is a crucial process in many industries, and achieving a high level of purity is often essential. With advances in technology, such as pervaporation membrane separation, the process of ethanol dehydration is becoming more efficient and environmentally friendly. As the demand for high-purity ethanol continues to grow, so too will the importance of effective and efficient ethanol dehydration methods.