Are you looking for an efficient and environmentally-friendly dehydration solution for your chemical process? Discover the innovative pervaporation membrane technology used by Xiamen Vitamin Company for ethyl ether dehydration, providing remarkable product recovery rates and numerous advantages over traditional methods.

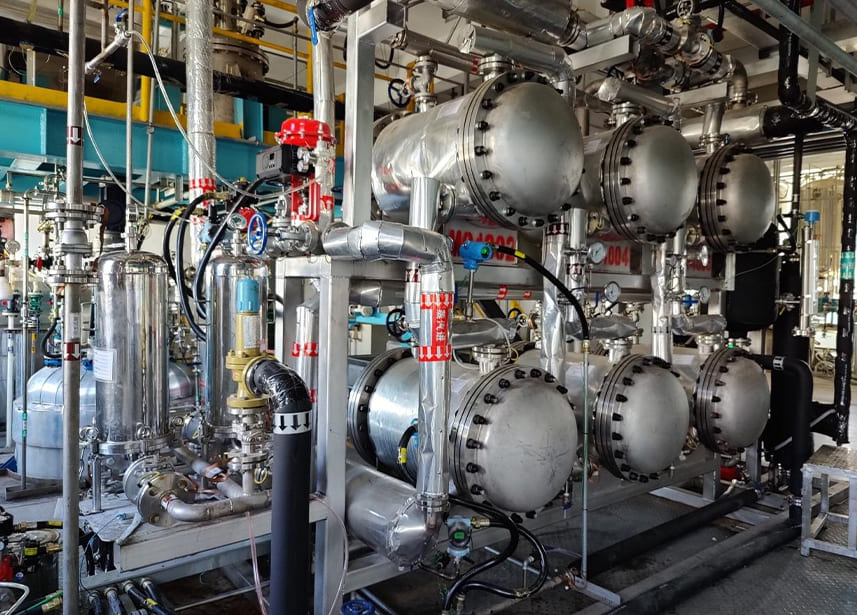

Xiamen Vitamin Company’s ethyl ether dehydration process, handled by Damo technology, with an annual production capacity of 2,400 tons, reduces water content from 10% to 1% and maintains a pH value of 4-5. They utilize unique liquid-phase equipment and proprietary pervaporation membrane technology, achieving stable operation for over a year and an impressive product recovery rate of 99%.

Keep reading to learn how pervaporation membrane technology works and the benefits it offers in terms of efficiency, energy savings, environmental friendliness, safety, and simplicity.

How Damo PV Membrane Technology Works

Damo PV membrane is a high-efficiency separation technique that enables molecular separation. Small molecules selectively pass through the membrane, while larger molecules have difficulty permeating it. This results in efficient separation between molecules. In this project, water molecules (0.29mm) are smaller than the organic solvent molecules (ether), and the inorganic membrane pore size is between these two sizes. This allows for efficient separation of water molecules from the organic solvent mixture, yielding ultra-low water content organic solvent products.

Benefits of Pervaporation Membrane Separation Solution

High efficiency and energy-saving

The technology boasts a high single-pass recovery rate, with permeate recovery and utilization reaching over 99%. Compared to traditional distillation and adsorption technologies, it can save 30-50% more energy.

Environmentally-friendly

No third component is required, and the permeate can be recycled and reused, minimizing waste and reducing environmental impact.

Safe and simple

The process is controlled and monitored automatically through PLC and HMI systems, with a safety interlock protection system ensuring a high level of automation and safety.

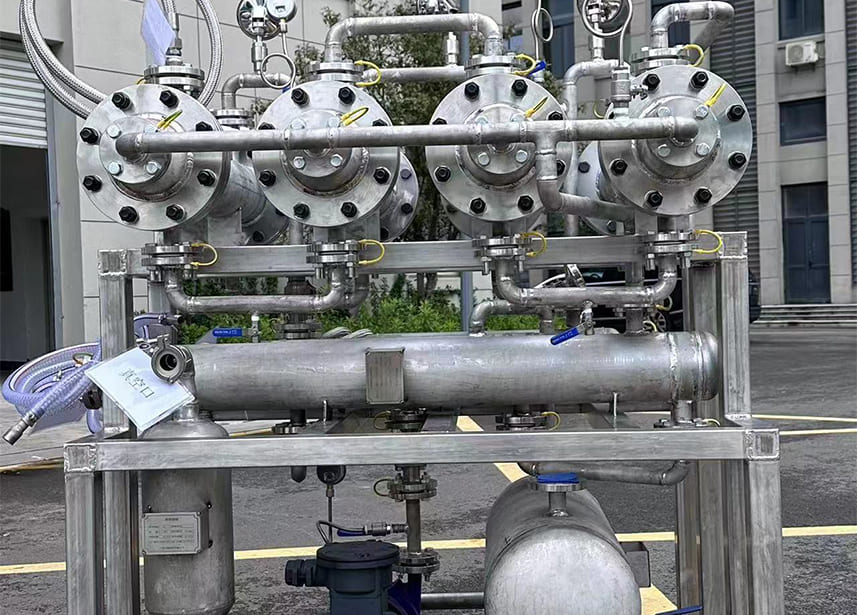

Skid-mounted equipment

The technology takes up minimal space, is easy to install and maintain, has low equipment height, and features a modular design for simple maintenance without the need for extensive infrastructure.

Conclusion

Xiamen Vitamin Company’s use of pervaporation membrane technology for ethyl ether dehydration demonstrates the potential of this innovative process for chemical industries. With its high efficiency, energy savings, environmental benefits, safety, and simplicity, this technology offers a superior alternative to traditional dehydration methods. Consider adopting pervaporation membrane technology in your own chemical processes to achieve similar outstanding results.