Are you facing challenges with acetonitrile dehydration in your pharmaceutical production? Learn how Damo’s cutting-edge pervaporation membrane technology helped a Fujian-based pharmaceutical company achieve remarkable dehydration results and streamline their production process.

Damo’s pioneering pervaporation membrane technology is designed to efficiently separate mixtures based on the different dissolution and diffusion rates of their components. This innovative technology is not affected by azeotropic limitations and doesn’t require a third component, making it an environmentally-friendly, scalable, and versatile solution.

Discover the impressive performance of Damo’s technology in a Fujian pharmaceutical company’s acetonitrile dehydration project and how it can address your own dehydration needs.

Impressive Results in Acetonitrile Dehydration

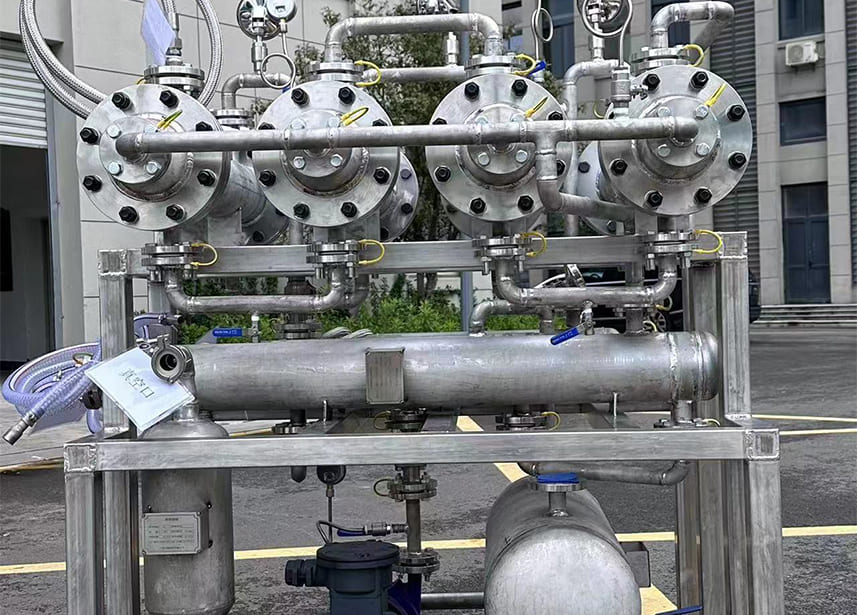

With Damo’s pervaporation membrane technology, the Fujian pharmaceutical company successfully dehydrated acetonitrile from 21% water content to just 1%. This was achieved using liquid-phase equipment, with an annual production capacity of 2,000 tons.

Damo’s PV membrane technology is an exceptional solution for companies in the pharmaceutical industry and other sectors looking to address their dehydration needs. The success of the Fujian pharmaceutical company’s acetonitrile dehydration project is just one example of how this cutting-edge technology can improve efficiency and product quality while minimizing environmental impact.

Damo Technology’s Leadership in Acid-Resistant Pervaporation Membranes

Damo is a leader in acid-resistant (pH<5) pervaporation membrane products both domestically and internationally. The company’s solutions are primarily used in the production and recovery of organic solvents, high-purity reagents, and VOCs across various industries, including biopharmaceuticals, new energy, electronics, and food.

Pervaporation Membrane Separation Technology Explained

Pervaporation membrane separation solution is based on the different dissolution and diffusion rates of components in a solvent mixture. This process is not affected by azeotropic limitations, and it doesn’t require the addition of a third component. This results in no secondary pollution, making the technology easy to scale and combine with other processes.

Damo’s pervaporation membrane technology has proven its worth in the pharmaceutical industry, showcasing its ability to tackle dehydration challenges and meet customer needs. By adopting this innovative technology, companies can improve their production efficiency, reduce environmental impact, and enhance product quality.

In conclusion, Damo’s pervaporation membrane technology offers an efficient, eco-friendly, and scalable solution for acetonitrile dehydration in the pharmaceutical industry. By employing this cutting-edge technology, pharmaceutical companies can effectively address common pain points while improving their overall production process.

.